Laser cleaning for removing contaminants from brick surfaces

- Comparison of laser cleaning with traditional cleaning methods

- Types of contaminants that can be removed with laser cleaning

- Safety precautions for using laser cleaning on brick surfaces

- Environmental impact of laser cleaning

- Future developments in laser cleaning technology for brick surfaces

- Factors to consider when choosing a laser cleaning system for brick surfaces

- Applications of laser cleaning in historical preservation of brick buildings

- Role of laser cleaning in restoring the appearance of brick surfaces

Comparison of laser cleaning with traditional cleaning methods

Laser Cleaning

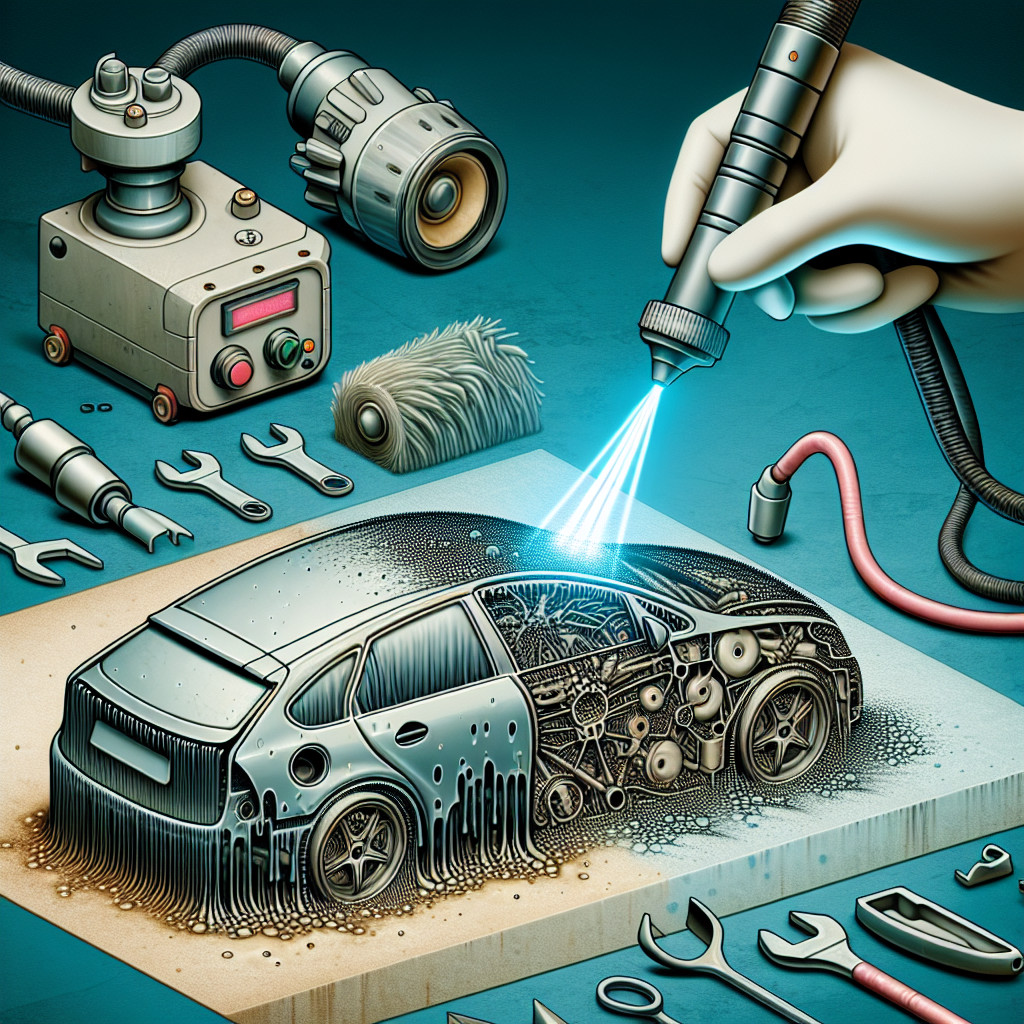

Laser cleaning is a non-contact, dry cleaning method that uses a high-intensity laser beam to remove contaminants from surfaces. The laser beam vaporizes the contaminants, leaving behind a clean surface without any residue. This method is highly precise and can be used on a wide range of materials, including metals, plastics, and ceramics.

- Advantages of laser cleaning:

- Non-contact cleaning

- High precision

- No chemicals or abrasives required

- Environmentally friendly

- Can be used on delicate surfaces

Traditional Cleaning Methods

Traditional cleaning methods like chemical cleaning, abrasive blasting, and ultrasonic cleaning have been widely used in various industries for many years. While these methods are effective in removing contaminants, they also have some drawbacks compared to laser cleaning.

- Disadvantages of traditional cleaning methods:

- Chemical cleaning can be harmful to the environment

- Abrasive blasting can damage surfaces

- Ultrasonic cleaning may not be suitable for all materials

- These methods can be time-consuming and labor-intensive

Conclusion

Overall, laser cleaning offers a superior alternative to traditional cleaning methods. Its precision, efficiency, and environmental friendliness make it a preferred choice for many industries. While traditional methods still have their place, laser cleaning is quickly becoming the go-to solution for companies looking to improve their cleaning processes.

Hashtags: #lasercleaning #industrialcleaning #environmentallyfriendly #precisioncleaning

Keywords: laser cleaning, traditional cleaning methods, precision, efficiency, environmental friendliness

Long-tail phrases: comparison of laser cleaning with traditional methods, advantages of laser cleaning, disadvantages of traditional cleaning methods

Types of contaminants that can be removed with laser cleaning

- Rust: Laser cleaning can effectively remove rust from metal surfaces, restoring them to their original condition.

- Paint: Paint can be easily stripped off surfaces using laser cleaning, making it a popular choice for refinishing projects.

- Oil and grease: Laser cleaning can quickly and efficiently remove oil and grease from machinery and equipment, improving their performance and longevity.

- Corrosion: Laser cleaning is an effective way to remove corrosion from metal surfaces, preventing further damage and extending the lifespan of the material.

- Scale: Scale buildup on surfaces can be easily removed with laser cleaning, improving the efficiency of equipment and machinery.

- Adhesives: Laser cleaning can effectively remove adhesives from surfaces without damaging the underlying material, making it a versatile solution for a wide range of applications.

Overall, laser cleaning is a versatile and efficient method for removing a wide range of contaminants from various surfaces. Whether you need to remove rust, paint, oil, corrosion, scale, or adhesives, laser cleaning can provide a fast and effective solution.

Hashtags: #laser #cleaning #contaminants #rust #paint #oil #grease #corrosion #scale #adhesives

Keywords: laser cleaning, contaminants, rust, paint, oil, grease, corrosion, scale, adhesives

Safety precautions for using laser cleaning on brick surfaces

| Precaution | Description |

|---|---|

| Wear protective gear | Always wear appropriate protective gear, such as safety goggles and gloves, to protect yourself from potential hazards. |

| Ensure proper ventilation | Make sure that the area where the laser cleaning is taking place is well-ventilated to prevent the buildup of fumes and vapors. |

| Follow manufacturer’s instructions | Read and follow the manufacturer’s instructions for the laser cleaning equipment to ensure safe and proper use. |

| Keep bystanders at a safe distance | Ensure that bystanders are kept at a safe distance from the laser cleaning area to prevent accidents or injuries. |

| Inspect the brick surface | Before starting the laser cleaning process, inspect the brick surface for any cracks, damage, or other issues that could affect the cleaning process. |

By following these safety precautions, you can ensure that the laser cleaning process is carried out safely and effectively, resulting in clean and restored brick surfaces.

#safety #precautions #laser #cleaning #brick #surfaces

Keywords: laser cleaning, brick surfaces, safety precautions, protective gear, ventilation

Long-tail phrases: safety precautions for using laser cleaning on brick surfaces, effective methods for removing dirt from brick surfaces, proper use of laser cleaning equipment.

Environmental impact of laser cleaning

Impact on air quality

One of the main concerns with laser cleaning is the emission of particulate matter and gases into the air. The process can generate fumes and smoke, which may contain harmful substances such as metal oxides or volatile organic compounds (VOCs). These emissions can contribute to air pollution and have negative effects on human health and the environment.

Energy consumption

Laser cleaning requires a significant amount of energy to operate. The lasers used in the process consume electricity, which may come from non-renewable sources such as coal or natural gas. This can contribute to greenhouse gas emissions and climate change. It is important to consider the energy efficiency of laser cleaning systems and explore ways to reduce their environmental impact.

Waste generation

Another environmental concern associated with laser cleaning is the generation of waste. The process can produce hazardous waste materials, such as contaminated abrasives or coatings. Proper disposal of these materials is essential to prevent contamination of soil and water sources. Recycling and reusing waste materials can help minimize the environmental impact of laser cleaning.

Conclusion

While laser cleaning is a powerful tool for removing surface contaminants, it is important to consider its environmental impact. By addressing issues such as air emissions, energy consumption, and waste generation, we can minimize the negative effects of this technology on the environment. Sustainable practices and technologies can help make laser cleaning more environmentally friendly in the long run.

| Environmental Impact | Considerations |

|---|---|

| Air Quality | Emission of particulate matter and gases |

| Energy Consumption | Use of electricity from non-renewable sources |

| Waste Generation | Production of hazardous waste materials |

#environment #laser #cleaning #airquality #energyconsumption #wastegeneration

Environmental impact, laser cleaning, air quality, energy consumption, waste generation.

Future developments in laser cleaning technology for brick surfaces

Advancements in laser technology

Laser cleaning technology has come a long way since its inception. The use of lasers for cleaning brick surfaces has become more efficient and effective. With advancements in laser technology, we can expect to see even better results in the future.

Improved precision

One of the key developments in laser cleaning technology for brick surfaces is improved precision. Laser systems are now able to target specific areas on the brick surface, ensuring a thorough and precise cleaning process.

Increased power

Another important development is the increased power of laser cleaning systems. Higher power lasers can remove dirt, grime, and other contaminants from brick surfaces more effectively, leading to cleaner and brighter bricks.

Future applications

As laser cleaning technology continues to evolve, we can expect to see new applications for cleaning brick surfaces. From historical buildings to modern structures, laser cleaning technology will play a crucial role in preserving and maintaining brick surfaces.

Environmental benefits

One of the key advantages of laser cleaning technology is its environmental friendliness. Unlike traditional cleaning methods that use harsh chemicals, laser cleaning is a clean and sustainable solution for cleaning brick surfaces.

Cost-effective solutions

With advancements in laser technology, we can expect to see more cost-effective solutions for cleaning brick surfaces. Laser cleaning technology offers a long-term solution that reduces the need for frequent cleaning and maintenance.

Conclusion

In conclusion, the future of laser cleaning technology for brick surfaces looks bright. With advancements in laser technology, we can expect to see improved precision, increased power, and new applications for cleaning brick surfaces. Laser cleaning technology offers environmental benefits and cost-effective solutions for preserving and maintaining brick surfaces.

#laser #cleaning #technology #brick #surfaces

Future developments in laser cleaning technology for brick surfaces, advancements in laser technology, improved precision, increased power, future applications, environmental benefits, cost-effective solutions.

Factors to consider when choosing a laser cleaning system for brick surfaces

1. Power and wavelength: The power and wavelength of the laser are crucial . Higher power lasers are more effective at removing tough stains and contaminants, while shorter wavelengths are better suited for cleaning delicate surfaces without causing damage.

2. Adjustability: A laser cleaning system with adjustable settings allows you to customize the cleaning process to suit the specific needs of your brick surface. Look for a system that offers adjustable power, pulse duration, and spot size for maximum flexibility.

3. Safety features: Laser cleaning can be a safe and effective cleaning method when used properly, but it is important to choose a system that includes safety features such as interlocks, beam shut-off mechanisms, and protective eyewear to prevent accidents and injuries.

4. Portability: If you need to clean brick surfaces in different locations or on different projects, consider a portable laser cleaning system that is easy to transport and set up. This will allow you to clean brick surfaces efficiently and effectively wherever you go.

5. Cost: Laser cleaning systems can vary widely in price, so it is important to consider your budget when choosing a system. While it may be tempting to opt for the cheapest system available, keep in mind that higher-quality systems may offer better performance and durability in the long run.

In conclusion, when choosing a laser cleaning system for brick surfaces, it is important to consider factors such as power and wavelength, adjustability, safety features, portability, and cost to ensure that you select the right system for your specific needs. By taking these factors into account, you can effectively clean brick surfaces and restore their beauty and durability for years to come.

#laser #cleaning #brick #surfaces

Keywords: laser cleaning system, brick surfaces, power, wavelength, adjustability, safety features, portability, cost

Long-tail phrases: , how to choose the right laser cleaning system for brick surfaces, benefits of laser cleaning for brick surfaces.

Applications of laser cleaning in historical preservation of brick buildings

One of the key advantages of laser cleaning is its ability to selectively target contaminants without affecting the surrounding brick surface. This precision makes it ideal for cleaning intricate architectural details such as decorative carvings or delicate masonry work. Laser cleaning can also be used to remove graffiti or other unwanted markings from historic buildings without causing any damage to the underlying brick.

Another benefit of laser cleaning is its non-invasive nature, which minimizes the risk of damage to the historic building during the cleaning process. Unlike traditional cleaning methods that can be abrasive or corrosive, laser cleaning is gentle and safe for use on fragile brick surfaces. This makes it an ideal choice for preserving the integrity of historic buildings while maintaining their original appearance.

Overall, laser cleaning offers a precise, gentle, and non-invasive solution for preserving the beauty and structural integrity of historic brick buildings. By using this advanced cleaning technology, preservationists can ensure that these architectural treasures remain intact for future generations to enjoy.

Keywords:

- laser cleaning

- historical preservation

- brick buildings

- cultural heritage

- non-invasive cleaning

Long-tail phrases:

- applications of laser cleaning in historical preservation

- benefits of laser cleaning for brick buildings

- precision cleaning for delicate masonry work

- non-invasive cleaning methods for historic structures

#laser #cleaning #historicalpreservation #brickbuildings #culturalheritage #noninvasivecleaning, laser cleaning, historical preservation, brick buildings, cultural heritage, non-invasive cleaning.

Role of laser cleaning in restoring the appearance of brick surfaces

One of the key advantages of laser cleaning is its precision. The intensity and duration of the laser beam can be adjusted to target specific areas of the brick surface, ensuring that only the contaminants are removed while leaving the underlying brick untouched. This level of control allows for a more thorough and consistent cleaning process compared to traditional methods.

In addition to removing dirt and grime, laser cleaning can also be used to remove graffiti, paint, and other stubborn stains from brick surfaces. The heat generated by the laser beam can break down these substances, making them easier to remove without the need for harsh chemicals or abrasive techniques.

Overall, laser cleaning is a versatile and efficient method for restoring the appearance of brick surfaces. Whether used for routine maintenance or as part of a larger restoration project, laser cleaning can help to rejuvenate the look of brick buildings and structures, preserving their beauty for years to come.

- gentle and effective cleaning

- precision and control

- environmentally friendly

- versatile applications

- restoring historic buildings

- removing graffiti and paint

- preserving the beauty of brick structures

#laser #cleaning #brick #surfaces #restoration #historic #preservation #graffiti #paint #environmentallyfriendly