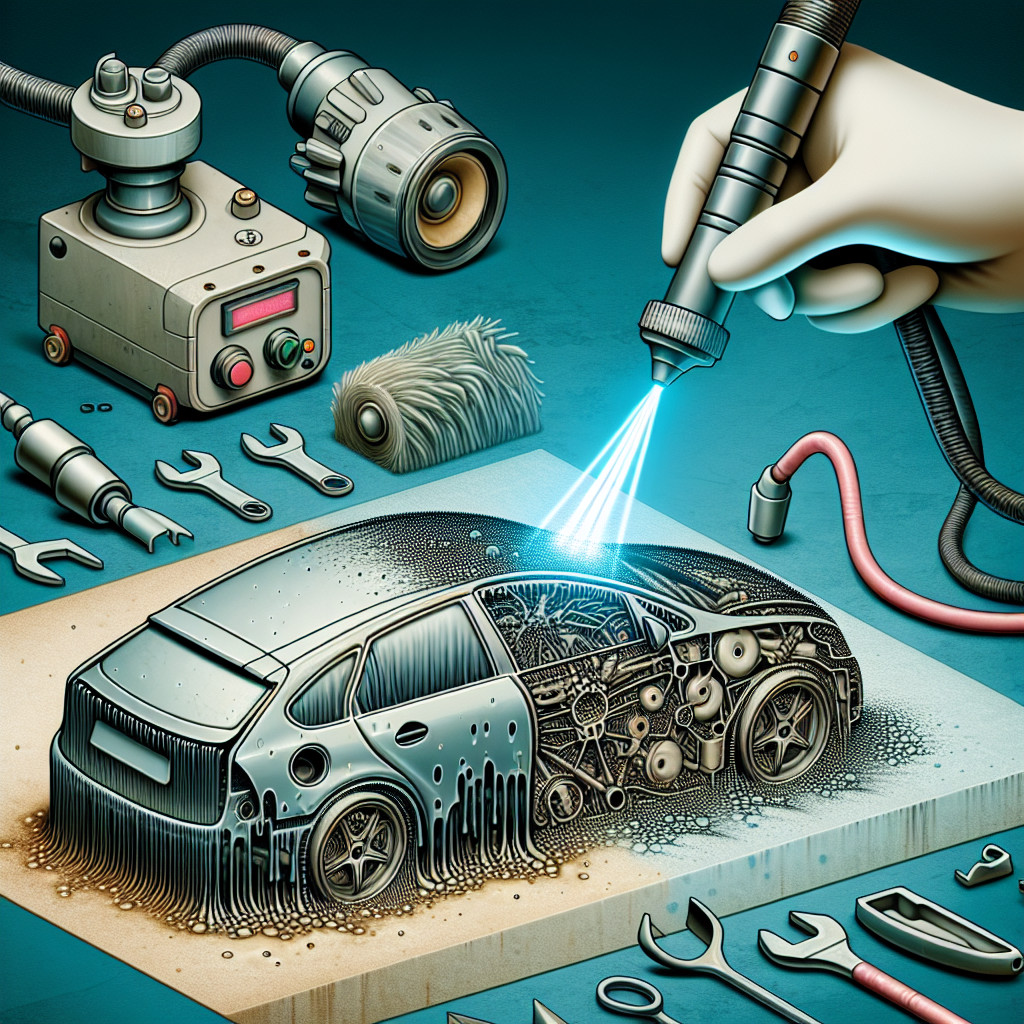

Laser cleaning for removing contaminants from plastic surfaces

- Applications of laser cleaning in the plastic industry

- Case studies of successful laser cleaning projects on plastic surfaces

- Cost-effectiveness of laser cleaning for plastic surfaces

- Benefits of using laser cleaning for restoring aged or discolored plastic surfaces

- Effectiveness of laser cleaning on removing residues from injection molding processes on plastic surfaces

- Comparison of laser cleaning with ultrasonic cleaning for plastics

- Challenges of cleaning intricate or complex plastic surfaces with laser technology

- Impact of laser cleaning on the surface roughness and texture of plastic components

Applications of laser cleaning in the plastic industry

Benefits of laser cleaning in the plastic industry

One of the main advantages of laser cleaning in the plastic industry is its precision. The focused laser beam can target specific areas on a surface, allowing for selective cleaning without affecting the surrounding material. This level of precision is especially important in industries where cleanliness is crucial, such as medical device manufacturing or electronics assembly.

Another benefit of laser cleaning is its versatility. The same laser system can be used to clean a variety of materials, including plastics, metals, and composites. This flexibility makes laser cleaning a cost-effective solution for manufacturers who work with different materials or need to clean a variety of surfaces.

Applications of laser cleaning in the plastic industry

One common application of laser cleaning in the plastic industry is the removal of mold release agents. These agents are used to prevent plastic parts from sticking to molds during the manufacturing process. However, if not properly removed, mold release agents can affect the adhesion of coatings or adhesives applied to the plastic parts. Laser cleaning offers a fast and efficient way to remove these contaminants without the need for harsh chemicals or abrasive methods.

Another application of laser cleaning in the plastic industry is surface preparation. Before bonding or painting plastic parts, it is important to ensure that the surface is clean and free of contaminants. Laser cleaning can quickly remove oils, greases, and other residues from plastic surfaces, creating a clean and uniform surface for further processing.

Conclusion

Laser cleaning is a versatile and precise technology that offers many benefits to the plastic industry. From removing mold release agents to preparing surfaces for bonding or painting, laser cleaning can improve the quality and efficiency of manufacturing processes. As the technology continues to advance, we can expect to see even more applications of laser cleaning in the plastic industry.

#laser #cleaning #plastic #industry #applications #precision #versatility #mold #release #agents #surface #preparation #manufacturing #technology #efficiency #processes

frazy kluczowe:

– laser cleaning in the plastic industry

– applications of laser cleaning

– precision in laser cleaning

– versatility of laser cleaning

– mold release agents removal

– surface preparation in plastic industry

Case studies of successful laser cleaning projects on plastic surfaces

Here are some notable :

1. Automotive industry: A leading car manufacturer used laser cleaning technology to remove paint overspray from plastic car parts. The laser was able to remove the overspray without damaging the underlying plastic surface, resulting in a clean and polished finish.

2. Electronics industry: A major electronics company utilized laser cleaning to remove dust and debris from plastic components of electronic devices. The laser was able to clean the components quickly and efficiently, ensuring optimal performance of the devices.

3. Medical industry: A medical device manufacturer employed laser cleaning to remove contaminants from plastic medical devices. The laser was able to sterilize the devices without the need for harsh chemicals, making it a safe and eco-friendly cleaning solution.

4. Aerospace industry: An aerospace company used laser cleaning to remove corrosion and oxidation from plastic aircraft components. The laser was able to restore the components to their original condition, ensuring the safety and reliability of the aircraft.

These case studies highlight the effectiveness of laser cleaning technology on plastic surfaces. The precision and versatility of laser cleaning make it an ideal solution for industries that require gentle yet thorough cleaning of delicate surfaces.

#laser #cleaning #plastic #surfaces #case #studies #successful #projects

Keywords: laser cleaning, plastic surfaces, case studies, successful projects, precision, versatility, gentle cleaning, delicate surfaces

Long-tail phrases: laser cleaning technology for plastic surfaces, successful case studies of laser cleaning on plastic, precision cleaning of plastic surfaces with laser technology.

Cost-effectiveness of laser cleaning for plastic surfaces

Laser cleaning for plastic surfaces can be cost-effective in the long run, despite the initial investment required for purchasing and maintaining the equipment. The efficiency of laser cleaning allows for faster cleaning times and reduced labor costs compared to manual cleaning methods. Additionally, laser cleaning eliminates the need for harsh chemicals and abrasive materials, reducing the overall cost of cleaning supplies.

Environmental impact

Another factor to consider when evaluating the cost-effectiveness of laser cleaning for plastic surfaces is its environmental impact. Laser cleaning is a sustainable and eco-friendly cleaning method that does not produce harmful waste or emissions. This can lead to cost savings in terms of compliance with environmental regulations and potential fines for improper disposal of cleaning chemicals.

Quality of cleaning

One of the key benefits of laser cleaning for plastic surfaces is its ability to provide a high-quality cleaning finish. The precision of laser technology allows for thorough removal of contaminants without damaging the underlying plastic surface. This can result in cost savings by reducing the need for rework or replacement of damaged parts.

Conclusion

In conclusion, the cost-effectiveness of laser cleaning for plastic surfaces depends on various factors, including the initial investment, efficiency, environmental impact, and quality of cleaning. While laser cleaning may require a higher upfront cost, the long-term benefits in terms of efficiency, sustainability, and quality make it a cost-effective cleaning solution for many industries.

- Efficiency

- Precision

- Environmental friendliness

- Quality

- Cost savings

- Cost-effectiveness

- Laser cleaning

- Plastic surfaces

- Environmental impact

- Quality of cleaning

cost-effectiveness, laser cleaning, plastic surfaces, environmental impact, quality of cleaning

#laser #cleaning #plastic #surfaces #costeffectiveness #environmentalimpact #qualityofcleaning #efficiency #precision #environmentalfriendliness #costsavings

Benefits of using laser cleaning for restoring aged or discolored plastic surfaces

1. Non-abrasive: Laser cleaning is a non-abrasive method, which means it does not damage the surface of the plastic. This is particularly important for delicate or sensitive plastic surfaces that may be easily scratched or marred by traditional cleaning methods.

2. Precision: Laser cleaning is a highly precise method that allows for targeted cleaning of specific areas on the plastic surface. This ensures that only the discolored or aged areas are treated, leaving the rest of the surface untouched.

3. Efficiency: Laser cleaning is a fast and efficient method that can quickly restore plastic surfaces to their original condition. This can save time and labor compared to traditional cleaning methods that may require multiple steps and treatments.

4. Environmentally friendly: Laser cleaning does not require the use of harsh chemicals or solvents, making it an environmentally friendly option for restoring plastic surfaces. This can help reduce the impact of cleaning on the environment.

5. Long-lasting results: Laser cleaning can provide long-lasting results, ensuring that the restored plastic surfaces remain in good condition for an extended period of time. This can help prolong the lifespan of the plastic and reduce the need for frequent cleaning and maintenance.

Overall, laser cleaning is a highly effective and efficient method for restoring aged or discolored plastic surfaces. Its non-abrasive nature, precision, efficiency, and environmental friendliness make it a preferred choice for many applications.

#laser #cleaning #plastic #restoration #aged #discolored

Keywords: laser cleaning, plastic surfaces, restoration, aged, discolored

Long-tail phrases: benefits of laser cleaning for plastic surfaces, precision cleaning for aged plastic, environmentally friendly restoration methods.

Effectiveness of laser cleaning on removing residues from injection molding processes on plastic surfaces

Several studies have investigated the effectiveness of laser cleaning on different types of residues, such as mold release agents, polymer degradation products, and other contaminants. These studies have shown that laser cleaning can effectively remove residues from plastic surfaces, leaving them clean and free of contaminants.

One of the advantages of laser cleaning is its precision and control. The laser beam can be focused on specific areas of the plastic surface, allowing for targeted cleaning without affecting the surrounding material. This level of precision is particularly important for delicate or complex parts where traditional cleaning methods may be ineffective or damaging.

Furthermore, laser cleaning is a fast and efficient process. It can be automated and integrated into existing production lines, reducing downtime and increasing productivity. This makes it a cost-effective solution for manufacturers looking to improve the quality of their products and streamline their production processes.

In conclusion, laser cleaning is a highly effective method for removing residues from injection molding processes on plastic surfaces. Its precision, efficiency, and environmental friendliness make it a valuable tool for manufacturers seeking to improve the cleanliness and quality of their products.

- precision

- efficiency

- environmentally friendly

- targeted cleaning

- automation

- removing residues from injection molding processes

- plastic surfaces

- laser cleaning

- manufacturing process

- contaminants

hashtags: #laser #cleaning #injectionmolding #plasticsurfaces #manufacturing

Comparison of laser cleaning with ultrasonic cleaning for plastics

Laser cleaning:

- Laser cleaning is a non-contact method that uses a high-energy laser beam to remove contaminants from the surface of plastics.

- The laser beam heats up the contaminants, causing them to vaporize and be removed from the surface without damaging the plastic substrate.

- Laser cleaning is precise and can be used to clean intricate shapes and hard-to-reach areas on plastics.

- However, laser cleaning can be expensive and may not be suitable for all types of plastics.

Ultrasonic cleaning:

- Ultrasonic cleaning uses high-frequency sound waves to create cavitation bubbles in a cleaning solution, which then implode and remove contaminants from the surface of plastics.

- Ultrasonic cleaning is effective for removing dirt, grease, and other contaminants from plastics.

- Ultrasonic cleaning is relatively inexpensive and can be used for a wide range of plastics.

- However, ultrasonic cleaning may not be as precise as laser cleaning and may not be suitable for delicate plastics.

Comparison:

When comparing laser cleaning with ultrasonic cleaning for plastics, several factors need to be considered, including cost, effectiveness, precision, and suitability for different types of plastics.

- Cost: Laser cleaning is generally more expensive than ultrasonic cleaning due to the high cost of laser equipment and maintenance.

- Effectiveness: Both laser cleaning and ultrasonic cleaning are effective for removing contaminants from plastics, but laser cleaning may be more precise in removing stubborn contaminants.

- Precision: Laser cleaning is more precise than ultrasonic cleaning and can be used for cleaning intricate shapes and hard-to-reach areas on plastics.

- Suitability: Ultrasonic cleaning is suitable for a wide range of plastics, while laser cleaning may not be suitable for all types of plastics.

In conclusion, both laser cleaning and ultrasonic cleaning are effective methods for cleaning plastics, but they have different advantages and limitations. The choice between the two methods will depend on the specific requirements of the cleaning task and the type of plastics being cleaned.

#laser cleaning, ultrasonic cleaning, plastics, contaminants, cost, effectiveness, precision, suitability, cleaning solution, cavitation bubbles, surface, substrate, intricate shapes, hard-to-reach areas, dirt, grease, delicate plastics

#non-contact method, high-energy laser beam, vaporize, implosion, high-frequency sound waves, cavitation bubbles, maintenance, stubborn contaminants, advantages, limitations, specific requirements, cleaning task.

Challenges of cleaning intricate or complex plastic surfaces with laser technology

Challenges:

- 1. Surface damage: Laser cleaning can potentially damage the plastic surface if not used correctly. The intensity and duration of the laser beam must be carefully controlled to avoid melting or warping the plastic.

- 2. Residue removal: Some contaminants may be difficult to remove with laser technology, requiring multiple passes or different laser settings to fully clean the surface.

- 3. Material compatibility: Not all types of plastic are suitable for laser cleaning. Some plastics may absorb too much of the laser energy, leading to damage or ineffective cleaning.

- 4. Cost: Laser cleaning equipment can be expensive to purchase and maintain, making it a less accessible option for some industries or businesses.

- 5. Training: Proper training is essential for operators to use laser cleaning technology safely and effectively. Without proper training, there is a risk of accidents or damage to the plastic surface.

Benefits:

- Precision: Laser technology allows for precise cleaning of intricate or complex plastic surfaces, reaching areas that may be difficult to clean with traditional methods.

- Efficiency: Laser cleaning can be faster and more efficient than manual cleaning methods, reducing downtime and increasing productivity.

- Eco-friendly: Laser cleaning does not require the use of chemicals or solvents, making it a more environmentally friendly option for cleaning plastic surfaces.

- Versatility: Laser technology can be used on a variety of plastic surfaces, making it a versatile cleaning solution for different industries and applications.

Overall, while laser technology offers many benefits for cleaning intricate or complex plastic surfaces, it also comes with its own set of challenges that must be carefully considered and addressed. With proper training, equipment, and techniques, laser cleaning can be a valuable tool for maintaining the cleanliness and integrity of plastic surfaces in various industries.

#laser #technology #plastic #cleaning #challenges #intricate #complex #surface #precision #efficiency #eco-friendly #versatility

frazy kluczowe:

– cleaning intricate plastic surfaces with laser technology

– challenges of cleaning complex plastic surfaces

– laser cleaning for intricate plastic surfaces

– plastic surface cleaning challenges with laser technology

Impact of laser cleaning on the surface roughness and texture of plastic components

Several studies have been conducted to investigate the . These studies have shown that laser cleaning can effectively remove contaminants from the surface of plastic components without significantly altering the surface roughness or texture. In fact, laser cleaning has been found to improve the surface roughness of plastic components by removing surface contaminants and smoothing out any irregularities.

One of the main advantages of laser cleaning is its ability to selectively remove contaminants from the surface of plastic components without affecting the underlying material. This allows for precise cleaning of delicate components without causing damage to the surface. In addition, laser cleaning can be used to remove a wide range of contaminants, including oils, greases, and adhesives, from the surface of plastic components.

In conclusion, laser cleaning has a positive impact on the surface roughness and texture of plastic components. It can effectively remove contaminants from the surface of plastic components without significantly altering the surface roughness or texture. Laser cleaning is a non-contact, environmentally friendly method of cleaning plastic components that offers precise cleaning without causing damage to the surface.

Keywords: laser cleaning, surface roughness, surface texture, plastic components

Long-tail phrases: impact of laser cleaning on plastic components, non-contact cleaning method, environmentally friendly cleaning technique

#laser #cleaning #surface #roughness #texture #plastic #components #environmentally #friendly #non-contact #precise #contaminants #aesthetics #irregularities #studies #investigate #improve #selectively #oils #greases #adhesives #delicate #damage #method #technique #long-tail #phrases.